Quick Links

Power Surfacing wins Gold Medal at SOLIDWORKS World! See nominating article - "nPower Makes SOLIDWORKS a Surfacing Monster" |

Editor's Pick of the Week |

Power Surfacing Demo by Mark Biasotti Senior Product Manager at Dassault Systems |

![]()

- Do you need to create SOLIDWORKS® geometry from scanned meshes?

- Do you need to recreate or modify existing parts?

- Do you need to convert meshes from other sources into SOLIDWORKS®?

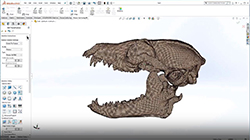

Power Surfacing RE (Reverse Engineering) is the solution you need to get your job done effectively and quickly. Our Power Surfacing RE product has a unique set of tools to allow you to rebuild shapes in SOLIDWORKS® from a large variety of polygonal meshes. It can import meshes from: 3D scanners, Finite Element Modeling, 3D sculpting programs, 3D printer files, other polygonal modeling tools, and online polygonal model databases. Power Surfacing RE has the ability to constrain to and reference underlying meshes to capture the original design shape. The Power Surfacing RE tools enable you to quickly define a Power Surface shape over the top of the referenced mesh. With the existing Power Surfacing tools you will be able to modify and evolve the design.

Learn about Power Surfacing RE 5.0 (view recorded webinar): view recorded Power Surfacing RE Webinar

Learn about the new techology for reverse engineering inside SOLIDWORKS: Sign up for Free 30 Min. Training Webinar

Please sign up for our Twitter feed:

![]() Click Here

Click Here

Features

- Includes the full Power Surfacing Toolset

- Import meshes and display as a reference mesh

- Convert existing SOLIDWORKS® geometry into reference mesh

- Drawing tools with automatic face creation

- Constrain points to reference mesh

- Automatic retopologizing of enclosed areas

- Add geometry to cover holes while matching curvature in reference mesh

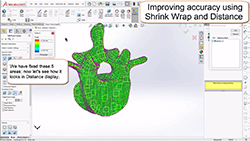

- Distance display to measure approximation of reference mesh

- Interpolate or "vacuum seal" to closely approximate the reference mesh shape

New in Version 6.1

The 6.1 release is a power packed upgrade for Power Surfacing RE. Version 6.1 is a big boost to workflow efficiency, making Power Surfacing RE a powerful, unmatched tool for reverse engineering scanned meshes, other meshes, or SOLIDWORKS® geometry. The 6.1 version also includes many new general Power Surfacing tools (which are all included in Power Surfacing RE). See the Power Surfacing product page for an overview of the new Power Surfacing 6.1 features. See a video highlighting the new Power Surfacing RE 6.1 features. Here is a list of some of the major Power Surfacing RE new 6.1 features.

- New Quad Wrap: improved for accuracy, speed, better topology. Will also automatically detect and close most open edges.

- Improved Shrink Wrap: automatically checks for and fixes many self-intersections.

- Mesh Smooth: new command that will smooth out the entire mesh. Great for messy imported mesh cleanup.

- Mesh Offset: Offset the mesh to make a thickness.

- Import point clouds (OBJ files)

Automated scanned mesh conversion

New automated conversion tools greatly simplify the process of converting scanned meshes into SOLIDWORKS® geometry.

video: Automated scanned mesh conversion

Superior accuracy

New patent pending technology allows customers to reverse engineer scanned meshes and capture / convert the fine details of the scanned mesh. Typically, capturing this high level of accuracy would create extremely large models (or even fail due to memory constraints). But with patent pending Power Surfacing RE technology, even large, highly detailed scans can be reverse engineered into accurate, editable SOLIDWORKS® geometry.

Follows curvature and mesh flow

Capturing the shape of a scanned mesh model is important, but it is also important to accurately follow the curvature and flow lines. Otherwise, creases, ridges, gullies and other features will wash out when converted into NURBS format. Power Surfacing RE uniquely follows the flow lines and features of the scanned mesh when converting it into NURBS / CAD geometry. The result is a super accurate, editable model, optimized for usage in the CAD environment.

Curvature driven surface knot density

Power Surfacing RE is highly intelligent in handling large scanned meshes. It uses patent pending technology to capture fine details, without bloating the model size. The result is an optimal, custom model based on the user's desired accuracy.

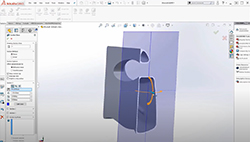

Topology Optimization

Power Surfacing RE can take SOLIDWORKS® "Topology Study" models and turn that data into usable SOLIDWORKS® solids geometry.

video: Topology Optimization

Semi-automated tools for finding and fixing anomolies

Even with the best scanners, the scanned meshes that are produced can have flaws and problems. Scanners may produce anomalies due to inaccuracy or scanning visibility (tears, rips, holes, overlaps, etc.). Scanned objects might also have edges or surfaces that are worn or damaged (the scanner may be accurate, but the objects themselves may be damaged); but users can restore those damaged edges / surfaces to their original, intended form using Power Surfacing RE. Power Surfacing RE has automated tools to identify the problem areas in the scanned mesh, and tools to fix those problems with a minimal amount of effort.

video: Advanced reverse engineering

Benefits

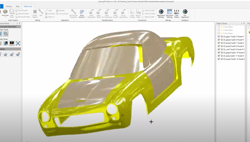

Power Surfacing RE allows the customer to reverse engineer free form organic shapes in SOLIDWORKS®. Existing products specialize in recreating precise prismatic parts from scanned meshes. However, dealing with organic / freeform shapes is extremely problematic...until now! Power Surfacing RE opens the doors to greater creativity and design flexibility. Now you are no longer limited to conventional design shapes. Power Surfacing RE allows you to reverse engineer human forms, animal shapes, car bodies, and other freeform representations.

Some of the industries that Power Surfacing RE supports include:

- - Industrial Design

- - Ergonomics

- - Sporting goods & clothing

- - Toys

- - Character design

- - Analysis of organic parts

- - Dental

- - Re-purposing existing designs

- - Handheld devices

- - Power tools

- - Jewelry

- - Cutlery

- - Furniture

- - Automotive

- - Art

- - Clay model digitizing

- - Cosmetics

Neither Sub-D (Subdivision Surface) modeling nor NURBS modeling can effectively solve all reverse engineering design problems. Each has strengths and weaknesses. Sub-D modeling is great at producing and modifying complex freeform / organic shapes with smooth surfaces. NURBS modeling is good at combining shapes via. Boolean and Feature operations as well as refining shapes with operations like filleting, blending and face editing. We really see Power Surfacing as a novel and powerful unification piece between these two technologies. Being able to use both modeling paradigms together in the reverse engineering process provides huge productivity advantages. Power Surfacing RE combined with SOLIDWORKS® parametric design provides SOLIDWORKS® users with a ground breaking reverse engineering toolkit.

Phone: +1-858-592-8866

Phone: +1-858-592-8866